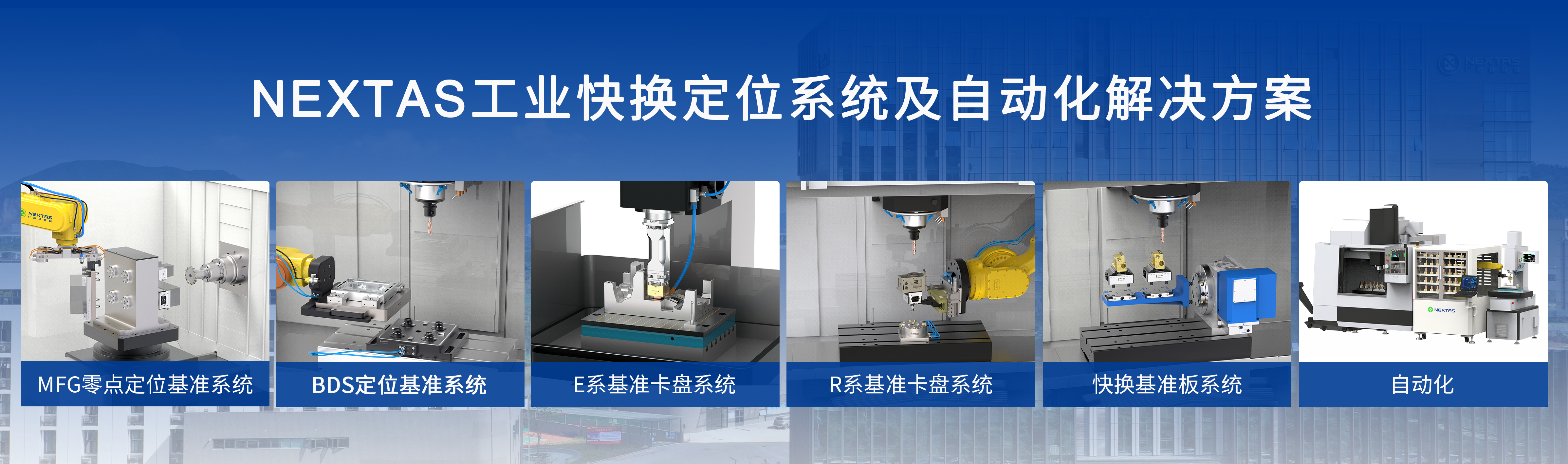

解决方案

不断创新与改进,只为您提供更优质的解决方案

产品系列

专注于自身技术的持续突破与创新,为客户提供优质产品

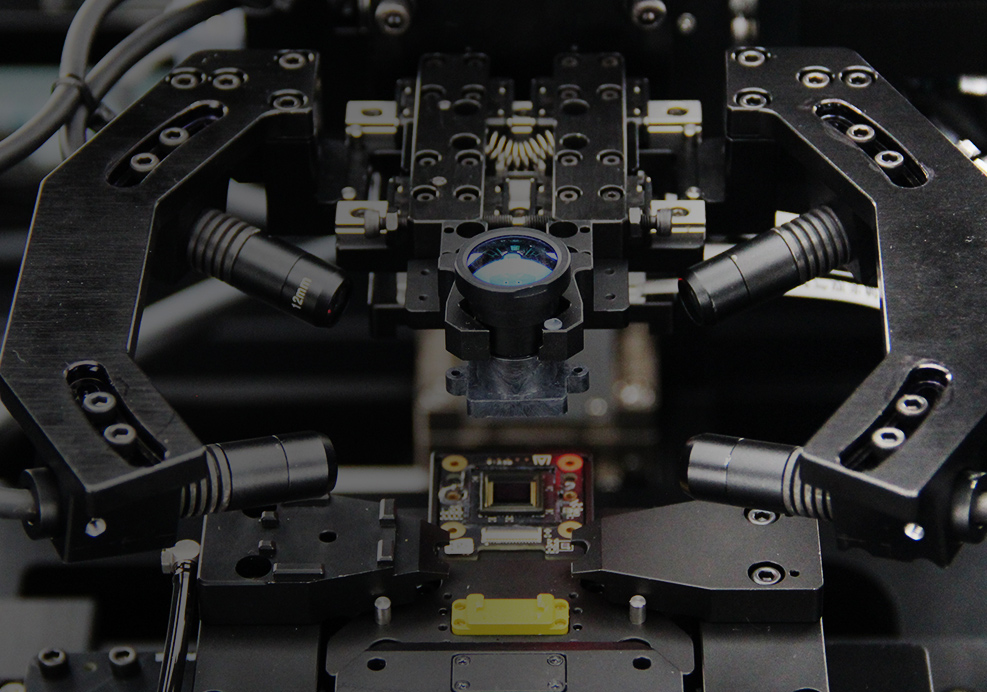

智能调测

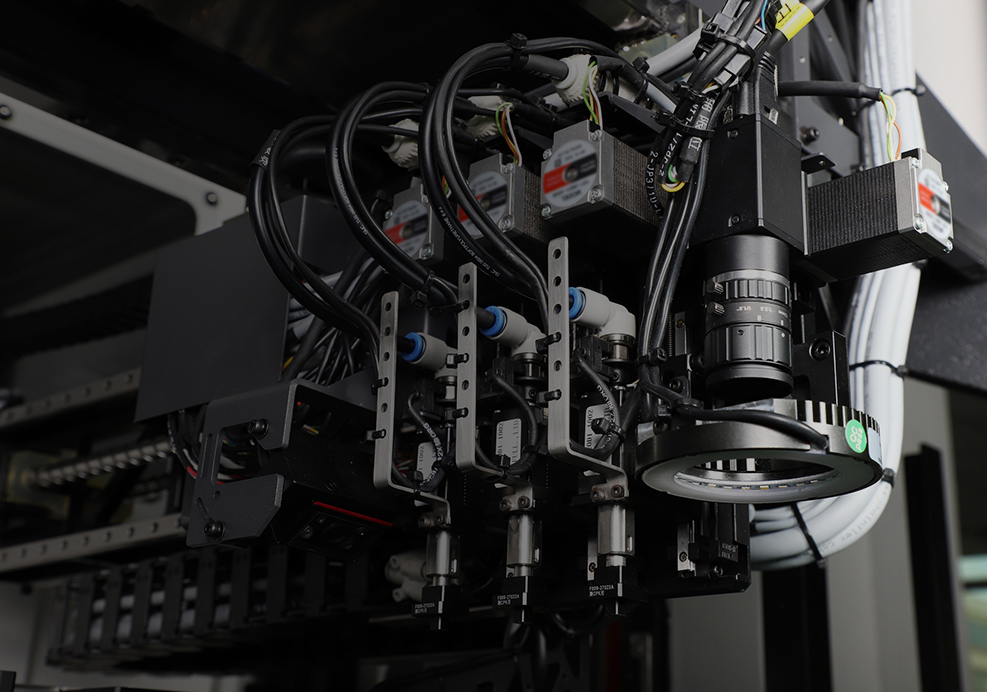

智能装配

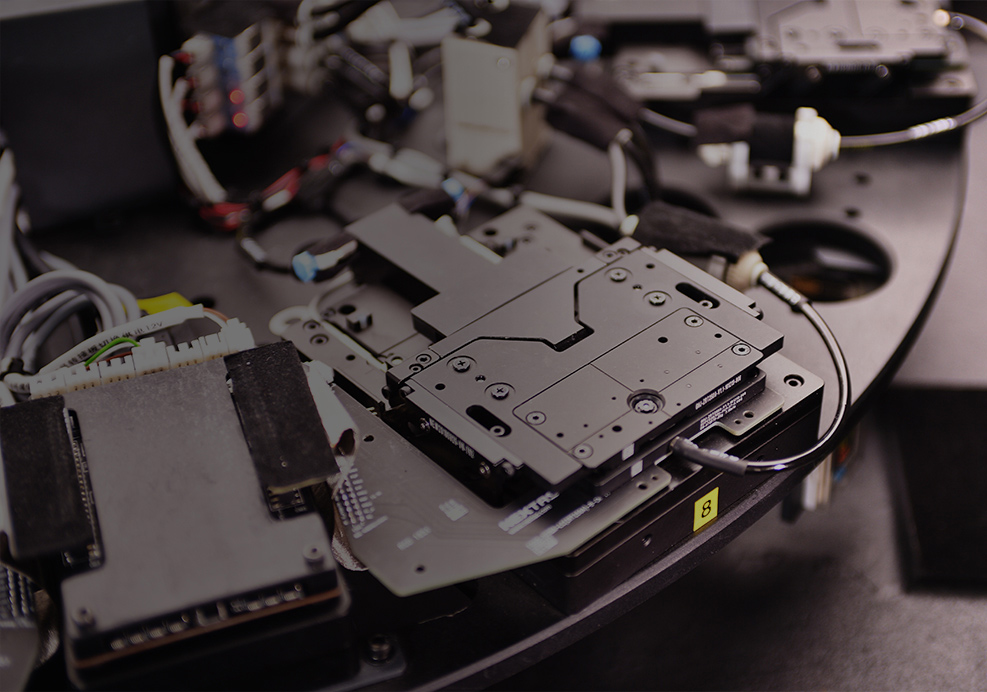

微针测试

关于广浩捷

珠海广浩捷科技股份有限公司成立于2009年,是一家以成像质量分析与机器视觉等为核心技术的自动化智能装备制造商。公司集研发、设计、生产、销售于一体,为下游客户提供智能调测设备、智能装配设备、微针测试治具等系列产品,并提供一站式整体解决方案...

14年 2009年成立 252项 已授权专利160+,受理中90+ 1000台 年销售设备1000+

资讯中心

-

10.24 节日快乐!

10.24程序员节快乐!

2020-10-24 -

智能自动化-助力CCM多元化高速发展

广浩捷公司于7月16日下午在深圳参加由旭日产研举办的“AI视觉引爆中国5G”的产业高峰论坛,本次论坛吸引了全产业链近千人参会,17位行业技术大咖登台演讲。

2020-07-17 -

“第十二届中国航空航天博览会”观展邀请

第十二届中国航空航天博览会(中国航展)将于2018年11月6日—11日在珠海航展中心精彩上演,距离我司仅8公里的速路程哦!

2018-10-13 -

我司将参加上海2016金属手机外壳加工成型与纳米注塑展览会

此次展会是国内专注于手机外壳加工成型盛会,我司自动智能贴装机器人设备(含双机器人、单机器人和龙门架式)将参加2016年上海手机金属外壳加工成型与纳米注塑展览会

2016-04-22